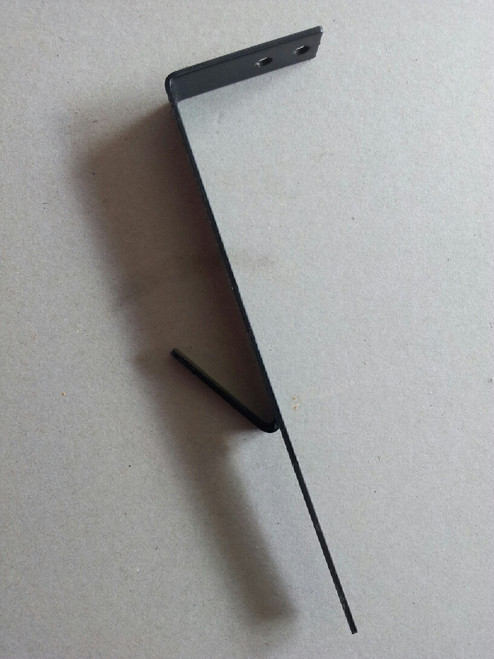

Product Description

2006 Kodak Trendsetter Quantum 400 II

Automated Complete system with rip

Print Console version 2.0

the machine has 2,168 hours of laser operation

The Kodak Trendsetter 400 III Quantum (circa 2006) was a high-performance, thermal Computer-to-Plate (CtP) system for the 4-page printing market, offering speeds up to 50 plates per hour with automation, superior Squarespot Imaging for accuracy, and support for Staccato Screening (10/20 micron) for photorealistic quality, built on the reliable Trendsetter platform, with options to upgrade speed or go to 8-up plates. It utilized Kodak THERMAL DIRECT (processless) plates, reducing chemistry and waste, and featured remote monitoring via a mobile app and integration with Kodak workflow.

Key Features & Specifications (around 2006):

- Type: External Drum Thermal Platesetter.

- Market: Ideal for 4-page printing (2- to 6-up).

- Throughput: Up to 43 plates/hour (standard), 50 plates/hour (with autoloader).

- Imaging: Kodak Squarespot Technology for consistent accuracy.

- Resolution: Up to 2400 dpi, 1200 dpi.

- Screening: Standard 20-micron or optional 10-micron Staccato.

- Media: Compatible with Kodak Thermal Direct (processless) plates.

- Automation: Available autoloaders (Autoloader, SCU, MCU) for continuous operation, handling slip sheets and rotations

- Connectivity: Workflow integration with Kodak systems and third-party solutions.

Benefits:

- Productivity: High throughput and automation reduced labor.

- Quality: Staccato screening and Squarespot tech delivered superior photorealistic results.

- Cost/Environment: Processless plates eliminated chemistry, reducing costs and environmental impact.

- Reliability: Built on the robust and easily maintainable Trendsetter platform.

In essence, the 2006 Trendsetter 400 III Quantum was a powerful, flexible, and future-proof CtP solution for printers needing high quality and efficiency in the 4-page

Certified Installation and Training Available.